Atmospheric humidity in the apartment - cause of the mold-formation

1. Interaction humidity and construction-mantle

1.1. Building material and humidity

1.2. The dew-water-formation and the humidity in the brickwork

2. Atmospheric humidity in the accomodation

2.1. Humidity in apartments

2.2. Gas-steam-mixture

2.3. Heat-demand for energy - gas-mixture and heating (ventilation-replacement)

2.4. Case in point ventilation-heat-requirement at a single-family home

3. The dampness-production and the ventilation-replacement

Online-calculation - atmospheric humidity, dew point and mold-formation

2. Atmospheric humidity in the accomodation

(Here, the absolute and relative humidity, the repletion-temperature and the water vapor-pressure play a role.) The humidity of the air is called water vapor, which one don't see, hears and can smell. Constantly, humidity increased in accomodations leads to healths risks, like chronic cough-attacks and asthmatic illnesses, in the extreme-case the danger of the consumption exists. Moisture-causes are many-layered in the predominant cases and can favor itself mutually.

2.1. Humidity in apartments

- Emergence of utilization (water vapor-production)

- Tub-bath 1 liter per person

Room-plant 0,5 until 1 liter per day

Respiration+ bodies, 1 people about. 0,1 liter per hour

Sleep-phase about. 1 l per person

To dry of washing 4,5 kg 1-1,5 liter

- Emergence of condition of the building

- Constructively in stock

- It weak-puts the construction

- Insides impacts

- Defective at water pipes, Spritzwasser in the bath

- Outer impacts

- Roof-area, leaky window menus, doors, walls through precipitation ascending humidity through defective stoppage in the foundation and ground floor-area

- In the new construction

- The construction-material-conditional addition of water for the mortar (gypsum, lime, concrete), earlier, one had "over the winter empty abandons" the new buildings, today, this must dry up through elevated heater and ventilation.[3]

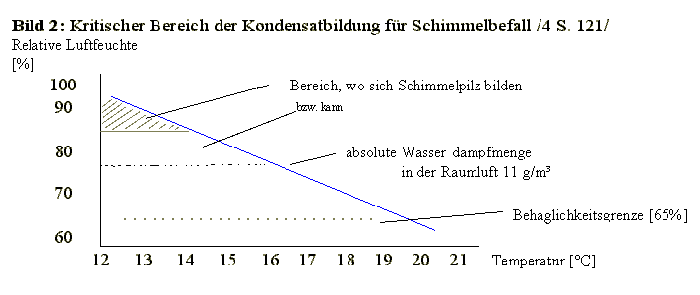

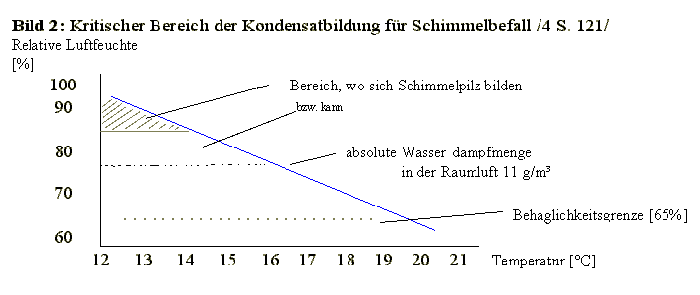

A too severe humidity in the accomodations, the comfort lie with approximately 65 per cent relative atmospheric humidity, this leads to the damage of the construction-body on the one hand and on the other hand has healths impacts and in the extreme-case, mold can refine. In the taking second place graphics, the dependence of the relative atmospheric humidity on the temperature is shown. The absolute atmospheric humidity is unchanged.

It becomes clear that the relative atmospheric humidity rises at a lowering of the air-temperature.

Table 1: Change of the relative atmospheric humidity from constant absolutely dampness and a temperature-alteration

| Temperature | relative humidity

with 11 g Wasser/m3Luft | rel. Humidity

with 8,3 g Wasser/m3Luft |

|---|

| 20 ºC | 65 % | 50 % |

| 18 ºC | 72 % | 55 % |

| 16 ºC | 81 % | 63 % |

| 14 ºC | 93 % | 71 % |

| 12 ºC | 100 % | 82 % |

If some component parts show a lower temperature than its surroundings on the basis of its construction-material-composition or through geometrical forms at its surface, so a higher relative atmospheric humidity exists at this plain. One can determine (moisture-falls) this observation at the panes of older construction.

Completion: Window menus new after the mounting with U = 1,1 W/m2K or the coolest plain is no more better at the pane so but at the the wall-construction and here one doesn't see the condensation. In a graphics, the dependence of the relative humidity on the temperature can is picked off.

Case in point 1: The air-temperature in the room amounts to 20 ºC with a relative humidity of 65 per cent. At a 36 brick-wall and the temperature amounts an outside-temperature of -10 ºC about at the inside. 14,2 ºC, this corresponds to a relative atmospheric humidity of about. 90 %. Now, however, it is not -10ºC every day and in a massive outside-wall, non-stationary circumstances are available, a consequence of the change of the temperature on the day and in the night as well as the influx of the sunshine (solar heat-storage). Normally, the relative atmospheric humidity is with normal utilization with 50 per cent in the winter or less before. The values result from the variation 2 (table 1) with it. Only the above named outside-wall is looked at, so a relative humidity of 71 per cent can appear with the extreme-case. The mold-formation doesn't occur with it under normal conditions either.

Case in point 2: We have the same wall-setup, 36er brick-walls on both sides plasters. Outside-temperature -10 ºC, the absolute humidity should remain same. A continuous nightly temperature-lowering takes place in order to save Heizenergie.

Table 2 (values are rounded)

| Room-temperature | absolute water vapor-content g/m3 | relative humidity | relative humidity at the inside of the outside-wall | more possibly growth of molds at the wall-surface of Isopletensystem |

| 20 ºC | 10,5 | 60 % | 85 per cent (with 14,2 ºC) | circa 6 days |

| 18 ºC | 10,5 | 67 % | 93 per cent (with 13 ºC) | circa 2 days |

| 16 ºC | 10,5 | 78 % | 100 per cent (with 11,4 ºC) | circa 1 days |

| 23 ºC | 10,5 | 51 % | 75 per cent (with 16,5 ºC) | no direct endangering |

They see, with the increase of the room temperature, the relative humidity sinks also simultaneously. But through the big heat-storage-capability of the massive wall, however, it takes a longer time until the temperature of the inside of the outside-wall of 13 ºC on 16,5 ºC rises. This appearance occurs exactly at the night-lowering. If the room temperature is increased again, for example from 18ºC to 23ºC, so the relative humidity remains very high at the wall-surface for long time.

Let's come to the next case, the measured relative humidity with the hygrometer should amount 60 per cent.

Table 3 (values are rounded)

| Room-temperature | absolute water vapor-content g/m3 | relative humidity | relative humidity at the inside of the outside-wall | more possibly growth of molds at the wall-surface of Isopletensystem |

| 20ºC | 10,5 | 60 % | 85 per cent (with 14,2 ºC) | circa 6 days |

| 18ºC | 9,2 | 60 % | 91 per cent (with 13ºC) | circa 20 days |

| 16ºC | 8 | 60 % | 77 per cent (with 11,4 ºC) | no direct endangering |

| 23ºC | 12,4 | 60 % | 89 per cent (with 16,5 ºC) | circa 1,5 days |

The room temperature should become considerations in an in-space-apartment, for example. On the day, the air-temperature 23 ºC (table 2) amounts, the relative humidity with 51 per cent is in order. The heater is switched off in the evening, the air-temperature sinks to 18 ºC (desired temperature to sleeping).) However, the temperature sinks with it at the outside-wall-surface of 16,5 ºC in direction 13ºC also after some hours. The relative humidity at the wall-surface increases from about so. 75 per cent (see table 2) on 93 per cent. In the most unfavorable case already would become after about. 1,5 days on the woodchip wallpaper higher mold-concentrations appears. However still last in stock a bedroom with the constant temperature of 16 ºC and an average relative humidity of 60 per cent, table 3, so no mold-formation occurs the rule here.

Of course, the room temperature doesn't sink so fast in the in-space-apartment. In order to reach a lower temperature, it is aired and the absolute, respectively relative humidity sinks. As well the massive brickwork has a corresponding heat-storage-capability at its disposal so that the surface temperature doesn't sink to 13 ºC but should lie between 14 and 15 ºC. But also here the relative humidity is already with over 80 per cent and the possible mold-formation is between 4 and 10 days.

(To the simplification, the dampness-production was not taken into account during the utilization, to it in the further implementation.)

It becomes clear in these simple cases in point that alone but also the temperature, the utilization-performance and further elements of a possible mold-formation can therefore be not only the relative humidity responsibly. It still becomes clear that a mold-freedom is available also with a low room temperature. The arguments, by heating, the mold-endangering is decreased, is not quite right with it. A Temperierung of the wall-plains is much right. This is not succeeded as thick as possible heat insulation alone by one in here heat-bridges being able to, for example appears that played only a subordinate role until now. Important is the type of the heater and the order, so that evenly preferably all wall-plains is warmed up. Such a heater is the radiation-heater. (It also becomes short in an older contribution to heaters of 1994 on the difference between Radiation and convection-heater entered.)

2.2. Gas-steam-mixture

That at the most occurring gas-steam-mixture is the air-water vapor-mixture, therefore this, which is available in the interior-air. Alterations now step with the individual sizes, absolute humidity, temperature, relative humidity and pressure on, so connections between these exist. What is always not taken into account with the ventilation until now is the Enthalpie of the gas-steam-mixture. That is, every status of the inner-air "comprises" a certain energy. If the relative atmospheric humidity therefore increases with same enthalpy, so the space-temperature sinks. In order to attach importance these to a same temperature, energy constantly must be supplied the air-water vapor-mixture. Also the enthalpy increases with it. If the two different air-mixtures, inner and outside-air, now are mixed by the ventilation, so the absolute dampness is reduced normally if the outside-air has a lower absolute dampness. This is normally when the outside-temperature is lower. (Exactly vice-versa, it takes place on warm days.) Therefore, this doesn't become drily at the ventilation of the cellar in the summer, but condensate refines at the cellar-wall-surface conceivably.) If the temperature of the outside-air is lower, the air-temperature of the mixed air sinks in the interior. Through heat-supply, this rises again to the desired room temperature. At the ventilation, not only the temperature-difference must therefore be evened out through heat-energy but also this, that flowed in already with the increase of the atmospheric humidity, to attach importance about the temperature to a level. In the following calculation, the situation is represented without going into the details more exactly. [5]

A simple ventilation-replacement should take place big rooms in a 50 m3. The air-temperature of the bedroom in the morning should amount to 17 °C with a relative atmospheric humidity of 85 per cent. The outside-air has a temperature of 5 °C with a relative atmospheric humidity of 90 per cent. After the simple air-replacement, the relative atmospheric humidity should amount 65 per cent

Calculation

Given: T = 17 ºC, phi = 85 per cent, p = 0,1 MPa, RG = 287,1 Nm/kgK Gas-constant Air, Rd = 461,5 Nm / kgK (Gas-constant water vapor). Water vapor, h = 44 kJ/kg (enthalpy) [sees Mollier-h, x-Diagramm for moist air], space-volumes 50 m3

mG = (p - phi x ps / RGT)V

mG = (105 N/m2- [0,85 x 1936,3]N/m2) / 287,1 Nm/kgK x 290K)x 50m3

mG = 59 kg of dry air

mD = (phi x ps/RDT)V

mD = (0,85 x 1936,3 Nm2/461,5 N/kgK x 290K) x 50 m3

mD = 0,615 kg of water vapor

Calculation of ps = 288,88(1,098 + J /100)8,02 [N/m2]

The water vapor-volume of corresponds 10,4 g/kg air from m D/m G (compare Mollier-Diagramm) respectively x 1=12,3 g/m3 aus 0,615 kg/50 m3air.

The calculation for 50 m3 outside-air takes place analogously like above. Following values yield

T = 5 ºC, phi =90 %, p = 0,1 MPa, m G = 62,1 kg dry air, m D = 0,306 kg water vapor respectively x 2 =6,1 g/m3air

The space and outside-air is mixed.

xm = mG1x1 +mx2x2 / mg1 + mg2

xm = 1,18 kg/m3 x 12,3 g/m3 + 1,2 kg/m3 x 6,1 g/m3 / 1,18 kg/m3 + 1,24 kg/m3

xm = 9,1 g wader vapor/m3air

It becomes a mixture-straight into the Mollier-h, x-Diagra plan. (see picture 2. The other values can be taken so. It yields for the Enthalpie 37,5 kJ/kg, t = 14ºC, phi = 90 per cent (relative atmospheric humidity).

Form 2: Two gas-steam-mixtures mix

Form 3: Senkunk of the relative humidity through heating of the gas-steam-mixture

It is arrived to a cooling of the Mischluft situated in the space. An energy-transfer took place with it. With 50 m3 if this amounts:

50 m3 x 1,18 kg/m3 (44 kJ/kg - 37,5 kJ/kg)= 383,5 kJ/kg

383,5 kJ/kg x 278 x 10-4 kWh / 1 kJ = 106 Wh

By the ventilation, the air was cooled down on 14 ºC. In order to reach again the inner-temperature of 17 ºC, a heat must from

2,5 kJ/kg x 50 m3 x 1,2 kg/m3 = 150 kJ

150 KJ x 2,78 x 10-4 KWh / 1 KJ = 41,7 Wh

is supplied (see picture 3).

The simple ventilation needs with the given beginning values

about. 148 Wh (from 106 Wh + 41,7 Wh) as well as. 533,5 kJ/kg heat-energy. So that no higher carbon-dioxide-concentration originates they in the space at the expiration, not the 1 º / oo border crosses, an airspace of 32 m3 is necessary for each adult with simple ventilation-change per hour. (See contribution ventilation). Also from this view and the necessity contaminant abzulüften, should in this space, if it is used by 2 people, who amount circa to ventilation-part payment 1,2 per hour. Since the dormitory is used 8 hours per day actually circa, an average minimum-ventilation of 0,4 per hour emerges on the day. (Minimum-ventilation is for long-shepherds somewhat more highly as well if the space is used on the day.) With this contemplation, the transfer of the humidity is neglected.

In the following section, the share of the ventilation-heat loss should be looked at. The Heat-passageway-coefficient becomes at first, decides 1). The bedroom shall an outside-wall-plain of 10 m2 with an unit of heat-transfer of 0,5 W/m2K and a window menu-share of 2,5 m2 with U = 1,5 W/m2K has. The calculation takes place after:

1 1 1

U = --- = ------------ = ----------------------

Rk Ri + R + Ra 1 1 1

---- + ---- + ----

hi Λ ha

The other areas to the neighbor-spaces are neglected, since approximately immediately should be the temperature-difference to these. A temperature-difference of 12 K (17ºC indoors and 5ºC outside) emerges.

(2,5 m2 x 1,5 W/m2K + 7,5m2 x 0,5 W/m2K x 12 K = 90,0 W.

Heat loss through ventilation 0,4 x 148 W = 59,2 W ~ 60 W

Heat loss through the outside-wall 90 W

Total-heat loss 150 W (per hour).

The share of the ventilation-heat loss amounts after it

Ventilation-heat loss x 100% 60 W x 100%

x% = ---------------------------- = ------------- = 40%

total-heat loss 150 W

By the EnEV and the further increase, low units of heat-transfer are stipulated. Therefore should be worth it for the outside-wall an unit of heat-transfer of 0,2 W/m2K and the window menus 0,8 W/m2K. This yields a heat loss with the same climatic conditions through the outside-wall:

(2,5 m2 x 0,8 W/m2K + 7,5m2 x 0,2 W/m2K, x 12 K = 42,0 W.

The share of the ventilation-heat loss with the improved heat insulation amounts after it

Ventilation-heat loss x 100% 60 W x 100%

x% = ---------------------------- = ------------- = 59%

total-heat loss 102 W

The assumed minimum-ventilation-part payment, that refers to the carbon dioxide-share in the ambient air, was used with this case in point. Since should consider amounted also other contaminants for itself this ventilation-part payment 0,8 per hour in the ambient air from residential-hygienic view, however. A ventilation-heat loss of 0,8 x 148 W emerges with it = 118,4 W ~ 118 W. If this value is applied with the improved heat insulation, so a ventilation-heat loss-share emerges from

118 W x 100%

x% = ------------ = 73,8% !!!

160 W

In order to avoid condensate-formation at the wall-surfaces, the space-humidity must be out-aired. If the ventilation-heats loss are considered a constant size, so the relationship with increasing heat insulation changes in favor of the ventilation. With a super-heat insulation, the ventilation-heat loss amounts the 3-fold one of the transmission-heat loss mathematically approximately. So that the relationship looks not so glaring, the ventilation-number is to be essentially reduced, one speaks of controlled ventilation. This is sealed reached by completely window menu and doors and an obligatory-ventilation.  These addition-ventilation worked over the separated chimney-train earlier and were operated over a small mechanical ventilation-tab per hand. Takes on with a day-consumption of circa 240 to 350 W the constantly current electro-ventilator today, per year 86 until 126 KILOWATTS of stream. An alternative is the heat recovery, that can reduce a part of the ventilation-heat loss. Has the disadvantage of the high plant technology expenditure and the continuous maintenance, however. Ventilation-technical primordia of bigger buildings and above all at administration buildings have been gone in for for many years. However completely different yielding a return and technical criterions are valid here.

These addition-ventilation worked over the separated chimney-train earlier and were operated over a small mechanical ventilation-tab per hand. Takes on with a day-consumption of circa 240 to 350 W the constantly current electro-ventilator today, per year 86 until 126 KILOWATTS of stream. An alternative is the heat recovery, that can reduce a part of the ventilation-heat loss. Has the disadvantage of the high plant technology expenditure and the continuous maintenance, however. Ventilation-technical primordia of bigger buildings and above all at administration buildings have been gone in for for many years. However completely different yielding a return and technical criterions are valid here.

From technical and yielding a return view, a border of the meaningful strength of a heat insulation is sedate. This lies approximately with an unit of heat-transfer of 0,4 to 0,5 W/m2K.

This results from the share of the ventilation-heat loss which increases with sinking unit of heat-transfer and from the curve of the theoretical unit of heat-transfer. (See contribution heat-passageway-coefficient)

If the EnEV further intensified, this only shows that the Entscheider have only low knowledge of thermodynamic connections at their disposal at the building and trust blindly theoretical treatises, that were refurbished optically in computer-models. The inhabitant turns into the sturgeon-element on that occasion as biological nature, because more and more it through Allergies and other healths restrictions on the Wärmedämm and heat-measures of economy carried out in the last years responds.

2.4. Case in point ventilation-heat-requirement at a single-family home

The ventilation-heat-requirement should be looked at strongly simplified for a single-family home with 140 m2 usable floor space. It should be estimated a minimum-ventilation-part payment of 0,5 per hour here. Since however, parking space or little used spaces so often are not aired needs, constantly should be aired 70 per cent of the Raumvolumens with this case in point.

Aerating this space-volumes emerges from

140 m2 x 0,7 = 98 m2

98 m2 x 2,6 m (space-height) of x 0,5 (ventilation-part payment) = 127,4 m3 ~ 127 m3.

The above calculated necessary heat for a simple ventilation amounts to 148 Wh (533,5 kJ / kg) per 50 m3 ambient air. This refers to a temperature-difference of indoors to outside from 12 K.

For the heat loss per 1 K temperature-differences and for 1 m3 ambient air emerges

533,5 kJ/kg / (50 m3 x 12 K) = 0,889 kJ / kg per m3K.

The

heat meet pay for hall / Leipzig lies with 3350 Kds / a. (Do be composed from medium number of the heat meets pay and the medium air-temperature of all Heiztage and lie with circa 6,1ºC for Leipzig/Halle. 20ºC are applicable to the inner-temperature, and a difference of 13,9 K emerges, it is contained already in the heat meet pay.) To Hamburg, 3375 are applicable and for Frankfurt 3030.

Calculation of the heat-requirement for the annual ventilation

Air-volumes 127 m2hour and 3350 Kds / a heat meets pay, heat loss 0,89 kJ / kg m3K, fuel oil L (42 MJ / kg).

0,89 kJ x 127 m3 x 3350 Kd x 24 h

---------------------------------- = 9087612 kJ/kg

kg m3 K h d

9087,612 MJ/kg / 42 MJ/kg = 216,37(Liter fuel oil)

The energy consumption for the ventilation with a ventilation-part payment of 0,5 per hour lies with circa 200 liters of fuel oil per year. A hygienic necessary ventilation (0,8 per hour) requires 320 liters of fuel oil per year circa. Should be mentioned here, however, that the necessary ventilation doesn't take into account with the calculation to the sufficient reduction of the relative humidity became. With a high dampness-emergence in the building, the necessary ventilation-part payment can then be bigger conceivably. As well, the efficiency of the heater is taken not into account. One can reckon with circa 2 liters of fuel oil per m2 of used floor area (98 m2) for the heat-requirement with a minimum-ventilation (0,5 per hour) for the ventilation. For a hygienically necessary ventilation, 3 liters of fuel oil per m2 are circa necessary. Here, however, one should take also the human performance into account. If it is very cold, one airs somewhat less and shorter. However, the pressure-difference counteracts, that occurs with a temperature-difference, so that a ventilation takes place over the joints. A part of the restrained ventilation becomes so balanced.

Summarizing can be said, that an additional heat-requirement, that originates through the ventilation, corresponds approximately to the consumption between 2 to 3 liters of fuel oil per floor area.

To the comparison from PENANCE [3]:

| Hygienic ventilation | Buildings | entire yearly-consumption of oil per floor area [liter/m2/Jahr] | Yearly-consumption of oil for ventilation [liter/m2/Jahr] | Ventilation-share |

| 0,5 per hour | Row house | 35,0 | 3,15 | 9 % |

| 0,5 per hour | detached single-family home | 42,0 | 3,4 | 8 % |

| 1,0 per hour | Row house | 39,6 | 6,3 | 16 % |

| 1,0 per hour | detached single-family home | 46,9 | 6,7 | 14 % |

| | | | |

1, the unit of heat-transfer marks the heat quantity, that through-goes in a hour through each square meter of a component part of known thickness in the permanence of the Heat-supply, if the temperature-difference between the air between both pages of this wall amounts to 1 K.

Divide 1 2 3

© Bauratgeber24.de | Content | Lookups | Handbook | 2/2006

These addition-ventilation worked over the separated chimney-train earlier and were operated over a small mechanical ventilation-tab per hand. Takes on with a day-consumption of circa 240 to 350 W the constantly current electro-ventilator today, per year 86 until 126 KILOWATTS of stream. An alternative is the heat recovery, that can reduce a part of the ventilation-heat loss. Has the disadvantage of the high plant technology expenditure and the continuous maintenance, however. Ventilation-technical primordia of bigger buildings and above all at administration buildings have been gone in for for many years. However completely different yielding a return and technical criterions are valid here.

These addition-ventilation worked over the separated chimney-train earlier and were operated over a small mechanical ventilation-tab per hand. Takes on with a day-consumption of circa 240 to 350 W the constantly current electro-ventilator today, per year 86 until 126 KILOWATTS of stream. An alternative is the heat recovery, that can reduce a part of the ventilation-heat loss. Has the disadvantage of the high plant technology expenditure and the continuous maintenance, however. Ventilation-technical primordia of bigger buildings and above all at administration buildings have been gone in for for many years. However completely different yielding a return and technical criterions are valid here.